Syntex Polycrystalline Cutting Tools

Polycrystalline tooling will effectively machine non-ferrous metals and highly abrasive non-metallic materials, including: Aluminum, Brass, Copper,Magnesium, Columbium, Rubber, Reinforced Plastic, Graphite, Ceramics, Fiberglass, Wood, many composites materials, and carbon fiber.

These tools can be used for turning, milling, boring, slotting, drilling, and most other machining operations where carbide, high speed steel, or especial coated tooling are being used on the above materials.

Production or repetitive runs- if you are using NC or CNC equipment on the proper material on daily basis with the same tooling, Syntex is essential to save money and time.

Hard to Machine Material- Syntex tooling paid for itself in two days on a glass filled phenolic machining application where intricate left and right hand profile tools required 1 hour for set up. Carbide tooling produces approximately 80 parts between setups, while Syntex tooling produced over 1600 parts eliminating 20 hours of downtime.

Syntex Polycrystalline Cutting Tools

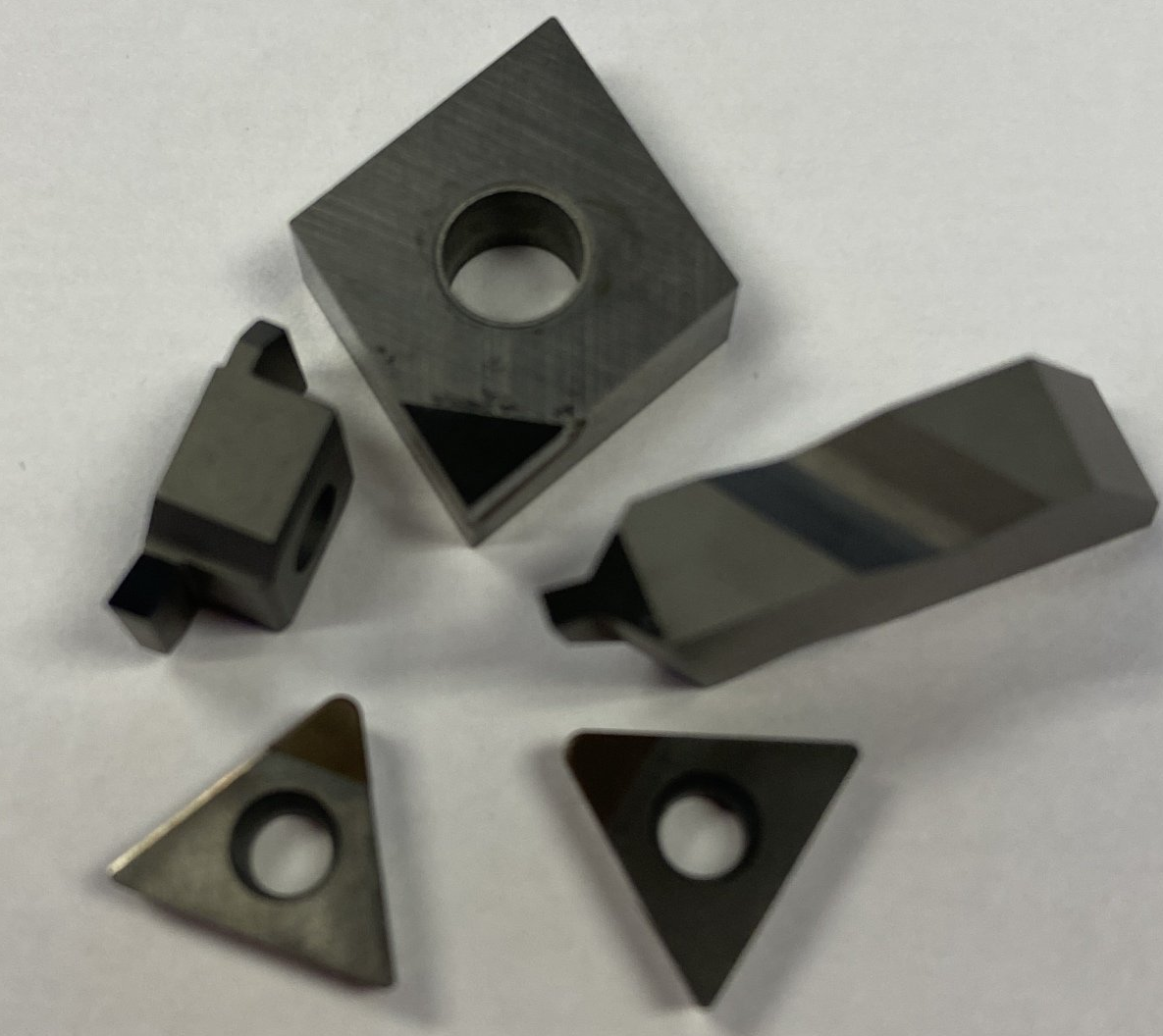

- PCD TIPPED INSERTS

- MEGADIAMOND INSERTS

- FULL TOP CBN INSERTS

- SOLID CBN INSERTS

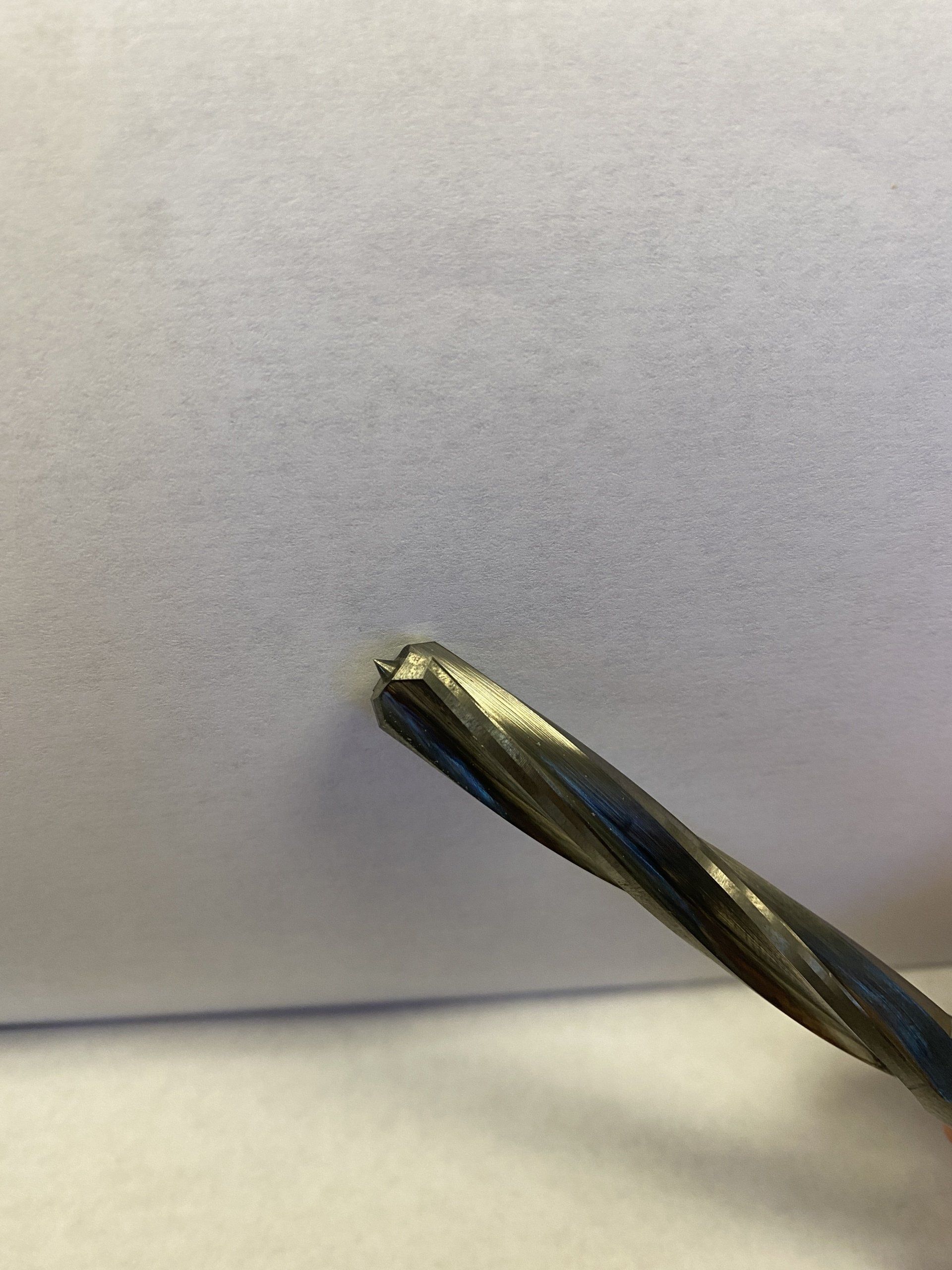

- PCD TIPPED DRILL

- PCD ROUTERS